Introduction

Rebuilding an engine is a significant undertaking, especially for heavy-duty trucks that demand robust performance and reliability. While an engine rebuild can breathe new life into your truck, there are several common mistakes that can undermine your efforts and lead to costly repairs. This blog post will highlight three critical mistakes to avoid when performing an engine rebuild on your heavy-duty truck, ensuring that your rebuild is successful and your truck remains reliable for years to come.

Mistake 1: Neglecting Proper Cleaning and Inspection

Why It’s Important

Proper cleaning and inspection of engine components are crucial steps in the rebuild process. Dirt, debris, and residues can cause significant damage if left inside the engine. Additionally, overlooking the condition of parts can lead to premature failures and reduced performance.

How to Avoid This Mistake

- Thorough Cleaning: Before reassembling your engine, ensure that all components are thoroughly cleaned. Use appropriate cleaning solutions and tools to remove any grime, oil residues, and carbon deposits. Pay special attention to small passages and crevices where debris can accumulate.

- Detailed Inspection: Carefully inspect all engine parts for wear, cracks, and other damage. Components like pistons, crankshafts, and camshafts should be measured for wear and checked for any signs of fatigue. Replace any parts that show excessive wear or damage to prevent future issues.

- Professional Help: If you’re unsure about the condition of certain parts or the thoroughness of your cleaning, consider seeking professional help. An experienced mechanic can provide valuable insights and ensure that your engine components are in top condition before reassembly.

Mistake 2: Using Incorrect or Low-Quality Parts

Why It’s Important

Using incorrect or low-quality parts can compromise the integrity and performance of your rebuilt engine. Heavy-duty trucks operate under extreme conditions, and substandard parts can lead to premature failures, reduced efficiency, and even catastrophic engine damage.

How to Avoid This Mistake

- OEM Parts: Always opt for Original Equipment Manufacturer (OEM) parts whenever possible. OEM parts are designed to meet the exact specifications of your engine and provide the reliability and durability required for heavy-duty applications.

- Quality Over Cost: While it might be tempting to save money by using cheaper aftermarket parts, this can be a false economy. Investing in high-quality parts will pay off in the long run by ensuring your engine rebuild lasts longer and performs better.

- Verify Compatibility: Ensure that all parts you purchase are compatible with your specific engine model. Using incorrect parts can lead to poor fitment and performance issues. Cross-reference part numbers and consult your truck’s service manual or a trusted mechanic to verify compatibility.

Mistake 3: Ignoring Manufacturer Specifications and Procedures

Why It’s Important

Manufacturer specifications and procedures are designed to ensure the optimal performance and longevity of your engine. Ignoring these guidelines can lead to improper assembly, reduced efficiency, and potential engine failures.

How to Avoid This Mistake

- Follow the Manual: Always refer to the manufacturer’s service manual for detailed instructions on the rebuild process. This includes torque specifications, assembly sequences, and clearances. Adhering to these guidelines ensures that your engine is rebuilt correctly and functions as intended.

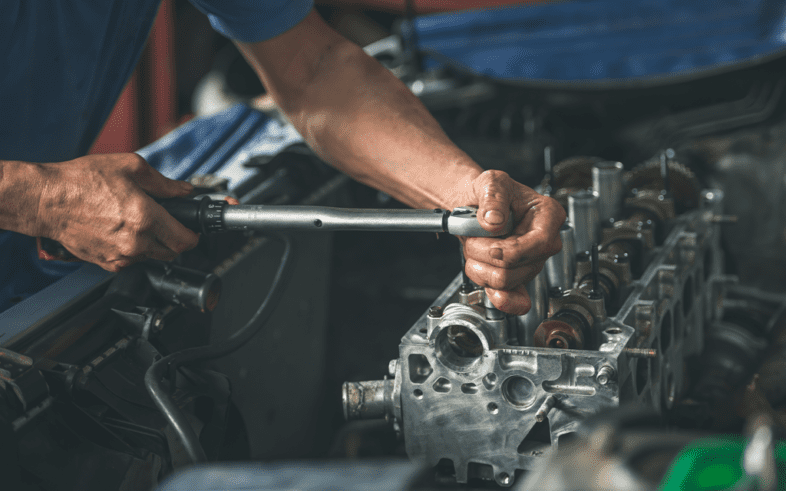

- Use Proper Tools: Utilizing the correct tools is essential for achieving precise measurements and assemblies. Torque wrenches, micrometers, and specialized engine rebuilding tools should be used to meet the manufacturer’s specifications accurately.

- Professional Training: If you lack experience in engine rebuilding, consider taking a course or seeking mentorship from a professional mechanic. Understanding the nuances of the rebuild process and the importance of each step can significantly improve the outcome of your project.

Conclusion

Rebuilding the engine of your heavy-duty truck is a complex task that requires attention to detail and adherence to best practices. By avoiding common mistakes such as neglecting proper cleaning and inspection, using incorrect or low-quality parts, and ignoring manufacturer specifications, you can ensure a successful rebuild that enhances the performance and longevity of your truck. Investing time and effort into getting these aspects right will pay off in the long run, providing you with a reliable and efficient engine capable of handling the toughest jobs.